Tungsten is a chemical element with the symbol W and atomic number 74. It is a dense, grayish-white metal that possesses exceptional properties making it highly valuable and important in various industries. Read More…

Edgetech Industries provides pure tungsten (rod, bar, sheet, plate, foil, crucible, tubing, customized parts), tungsten composites (CuW, CuWC, AgW, AgWC), tungsten alloys (W-Ni-Fe & W-Ni-Cu heavy alloys used as bucking bar, weights, radiation shielding, and raw tungsten (powder, trioxide, carbide) and granules/flux. We also provide tailor-made non-ferrous metals & alloys, rare earth elements,...

Titan International, Inc. is a dedicated supplier of quality products to the metal finishing industry. Through our partnering with a wide base of suppliers, Titan International is able to provide a broad metal product line. In addition to supplying high purity metals and metal powders, we will buy and/or sell your bulk scrap metal, including tungsten, tungsten carbide, nickel, and other metals.

Since 1987 our tungsten metal products have made us a leader in the worldwide market. Buffalo Tungsten is a tungsten supplier of tungsten metal powder & tungsten carbide powder used in tungsten bar & rod. Our tungsten wire is used in filament in light bulbs, electrical contacts & sports equipment.

At Global Tungsten & Powders (GTP), we have experience manufacturing and marketing products such as tungsten chemicals, tungsten carbide, and semi-finished tungsten parts. Industries we serve include aerospace, automotive, construction, and defense. We have established a global footprint for the production of tungsten materials by providing our customers with security of supply and continuous...

More Tungsten Suppliers

How Is Tungsten Mined?

Tungsten is primarily mined from two types of ore deposits: scheelite and wolframite. These deposits are found all over the world, with the largest producers being China, Russia, Canada, and Bolivia.

Scheelite is a calcium tungstate mineral with the chemical formula CaWO4. It typically occurs in various colors, including white, yellow, brown, and shades of green. Scheelite is an important ore mineral of tungsten and is primarily found in hydrothermal veins and greisen deposits. It often forms as tabular or prismatic crystals and has a high specific gravity. Scheelite is valued for its relatively high tungsten content and is a major source of tungsten used in various industrial applications.

Wolframite, on the other hand, is an iron-manganese tungstate mineral with the chemical formula (Fe,Mn)WO4. It is a solid solution series between the end members ferberite (FeWO4) and hübnerite (MnWO4). Wolframite is typically black or brown in color and is commonly found in quartz veins and pegmatites. It often occurs as elongated prismatic crystals or in dense aggregates. Wolframite is a significant source of tungsten and is commonly mined alongside other minerals, including cassiterite (tin ore). Its tungsten content makes it an important ore for the production of tungsten metal and tungsten alloys.

Both scheelite and wolframite are crucial sources of tungsten and are mined for their tungsten content. The extraction and processing of these minerals play a vital role in meeting the global demand for tungsten in various industries.

Tungsten mining involves several stages, beginning with prospecting and exploration to identify potential tungsten deposits. Once a suitable site is found, the mining process begins. The most common method of tungsten extraction is open-pit mining, particularly for large-scale operations. This process involves the use of heavy machinery, such as excavators and bulldozers, to remove the overlying soil and rock, exposing the tungsten-bearing ore. In some cases, underground mining may be employed, especially if the deposit is deeper or the ore quality justifies the additional cost. Underground mining utilizes tunnels and shafts to access the ore bodies.

Once the ore is extracted, it is then crushed into smaller pieces to facilitate further processing. The next step typically involves the beneficiation process, where the crushed ore undergoes physical or chemical treatments to separate the tungsten minerals from the waste materials. This can involve methods such as gravity separation, flotation, magnetic separation, or a combination of these techniques, depending on the specific ore characteristics.

After beneficiation, the resulting concentrate is further processed through various refining techniques. The most common refining method is roasting, where the concentrate is heated in the presence of air to remove impurities and convert the tungsten minerals into tungsten oxide (WO3). This oxide can then be chemically processed to obtain pure tungsten metal through a reduction process using hydrogen or carbon.

Overall, tungsten mining involves a series of steps, including prospecting, extraction, crushing, beneficiation, and refining, to transform the raw tungsten ore into a usable form for various applications.

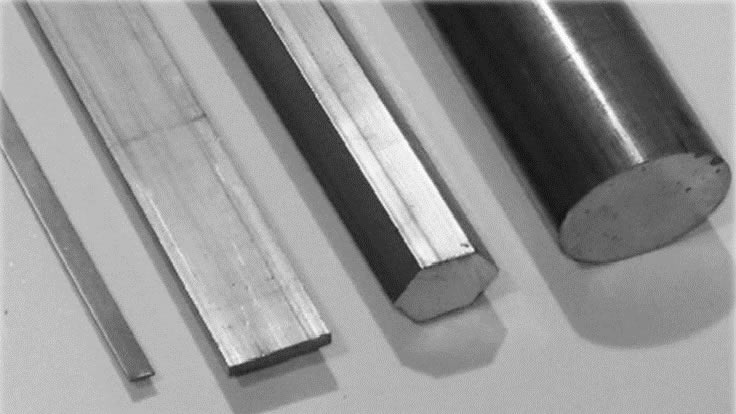

Common Tungsten Forms

Tungsten is found in various forms depending on its application and processing. One of the most common forms is tungsten oxide (WO3), which is produced during the refining process of tungsten ore. Tungsten oxide is a yellowish or bluish powder that serves as a precursor for the production of tungsten metal. It is also used in the production of tungsten alloys and as a catalyst in certain chemical reactions. Another common form is tungsten carbide (WC), a compound composed of tungsten and carbon. Tungsten carbide is extremely hard and is often used in the manufacturing of cutting tools, drill bits, and abrasives. It is known for its exceptional wear resistance and is highly valued in industries such as mining, construction, and machining. Additionally, tungsten alloys are widely utilized in various applications. These alloys typically contain tungsten along with other elements such as nickel, copper, iron, or cobalt. Tungsten alloys are sought after due to their high density, excellent strength, and good thermal and electrical conductivity, making them suitable for applications in aerospace, defense, electrical contacts, and radiation shielding.

Considerations with Tungsten

The mining and use of tungsten involve several considerations that are important to address. One key aspect is environmental impact. Tungsten mining can result in habitat disruption, soil erosion, and water pollution if not managed properly. Additionally, the extraction and processing of tungsten require energy and can contribute to greenhouse gas emissions.

Another consideration is worker safety and health. Tungsten mining often involves working in underground or open-pit mines, which can pose risks such as cave-ins, exposure to hazardous substances, and accidents involving heavy machinery. Social and ethical considerations also come into play, particularly in regions where tungsten is mined. Furthermore, the potential for conflict minerals, including tungsten, should be carefully addressed. Efforts must be made to prevent the sourcing of tungsten from conflict-affected regions and ensure responsible supply chain management to avoid contributing to human rights abuses and conflicts.

Manufacturers Address These Considerations

Tungsten manufacturers are increasingly recognizing the importance of addressing environmental, social, and ethical considerations associated with the production and use of tungsten. They are taking proactive measures to mitigate the impact of mining and processing operations on the environment. This includes implementing sustainable mining practices such as land reclamation, minimizing water usage, and adopting efficient waste management strategies to reduce pollution and ecosystem disruption.

To ensure worker safety and health, tungsten manufacturers are prioritizing the implementation of rigorous safety protocols, providing appropriate training, and adhering to occupational health and safety regulations. They are also actively engaging with local communities, supporting social development projects, and promoting responsible employment practices to benefit the local workforce.

In terms of ethical considerations, tungsten manufacturers are committed to responsible sourcing practices. They are working to establish transparent supply chains, conducting due diligence to identify and avoid conflict minerals, and complying with regulations such as the Dodd-Frank Act to ensure minerals, including tungsten, are sourced responsibly and do not contribute to human rights abuses or conflicts.

Furthermore, manufacturers are investing in research and development to explore cleaner and more sustainable technologies for tungsten extraction and processing. This includes exploring energy-efficient methods and adopting technologies that minimize greenhouse gas emissions and reduce the overall environmental footprint of tungsten production.

Collaboration within the industry, partnerships with NGOs, and engagement with stakeholders are also playing a crucial role in driving continuous improvement in responsible tungsten manufacturing practices. By actively addressing these considerations, tungsten manufacturers are striving to enhance sustainability, ethical sourcing, and social responsibility throughout the supply chain.

Regulations for Tungsten

In the United States, tungsten is subject to regulations aimed at promoting responsible sourcing and preventing the use of conflict minerals. These regulations are primarily implemented through the Dodd-Frank Wall Street Reform and Consumer Protection Act. Section 1502 of the act focuses on the sourcing of conflict minerals, which includes tungsten, from regions associated with human rights abuses and conflicts, particularly the Democratic Republic of the Congo (DRC) and surrounding countries. Under this law, publicly traded companies are required to disclose their use of conflict minerals in their products, conduct due diligence on their supply chains, and submit annual reports to the Securities and Exchange Commission (SEC) outlining the measures taken to ensure responsible sourcing. The aim is to prevent the funding of armed groups through the trade of minerals, including tungsten, and promote transparency and accountability in supply chains. These regulations play a crucial role in promoting ethical sourcing practices and encouraging companies to engage in responsible mineral supply chains.

Applications of Tungsten

Tungsten finds numerous applications across various industries due to its unique properties. One significant application is in the manufacturing of cutting tools, drills, and abrasives. Tungsten carbide, a composite material containing tungsten, is widely used in these tools due to its exceptional hardness and wear resistance. Additionally, tungsten’s high melting point makes it ideal for applications in high-temperature environments. It is utilized in light bulb filaments, where its ability to withstand intense heat ensures long-lasting illumination. Tungsten is also employed in rocket nozzles, where it withstands the extreme temperatures and pressures of space travel. Another notable application is in electrical contacts, where tungsten’s resistance to arcing and high electrical conductivity make it suitable for use in switches, relays, and circuit breakers. Tungsten’s high density makes it valuable for balance and counterbalance systems, as well as in aerospace components where weight is a crucial factor. Furthermore, tungsten alloys, renowned for their radiation shielding properties, are employed in medical imaging equipment, nuclear power plants, and aerospace applications to protect against harmful radiation exposure. These applications highlight the versatility and importance of tungsten in various industries.

Tungsten in the Energy Sector

One special application of tungsten involves its use in the energy sector. Tungsten plays a significant role in the energy sector, particularly in the realm of renewable energy technologies. In wind power generation, tungsten is utilized in the production of turbine blades. Its exceptional strength, durability, and resistance to high temperatures make it an ideal material for withstanding the demanding conditions of wind turbines. Tungsten carbide coatings are also applied to turbine components to enhance their performance and extend their lifespan. Furthermore, tungsten finds application in the energy storage sector, specifically in the production of lithium-ion batteries for electric vehicles (EVs). Tungsten is also used in battery anodes, where its high conductivity and stability enhance the overall performance and efficiency of the batteries.

What Does the Future of Tungsten Look Like?

The future of tungsten holds promising prospects driven by its unique properties and diverse applications. As technological advancements continue to unfold, the demand for tungsten is expected to remain strong. Tungsten’s hardness and wear resistance make it indispensable in industries such as manufacturing, construction, and mining, where tools and equipment must withstand demanding conditions. The increasing focus on renewable energy, including wind power and electric vehicles, is also likely to drive the demand for tungsten as it is used in the production of turbine blades and components for electric vehicle batteries. Moreover, the growing emphasis on energy efficiency and reducing greenhouse gas emissions may spur innovations in lighting technologies, where tungsten’s high melting point makes it a valuable component for advanced lighting systems. The medical field could also benefit from tungsten’s radiation shielding properties, as advancements in diagnostics and treatment methods continue. However, it is important to ensure sustainable and responsible mining practices to mitigate environmental impacts and address social considerations. Overall, with its exceptional properties and diverse applications, tungsten is poised to play a significant role in shaping future technologies and industries.

Choosing the Correct Tungsten Supplier

To ensure you have the most productive outcome when purchasing tungsten from a tungsten supplier, it is important to compare several companies using our directory of tungsten suppliers. Each tungsten supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each tungsten business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple tungsten companies with the same form.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

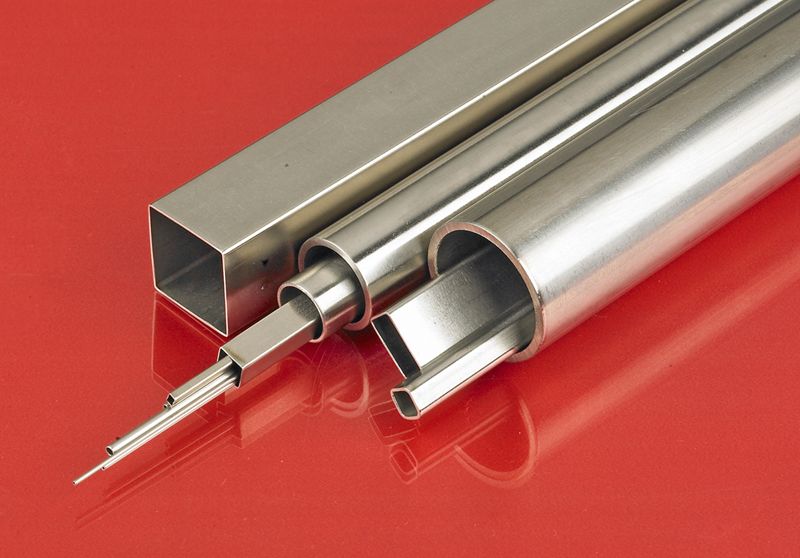

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services