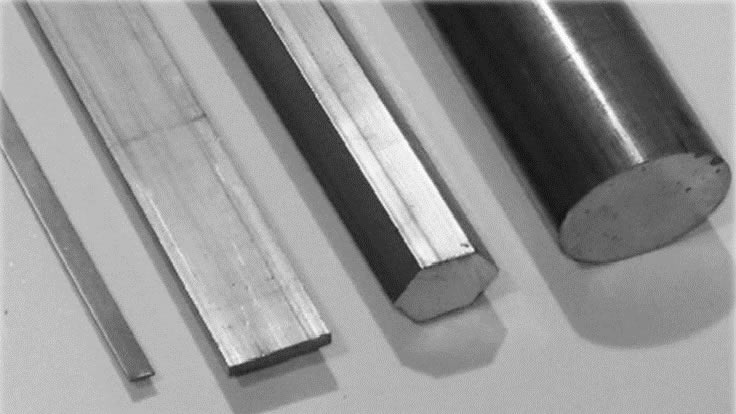

A Tungsten bar is made from 99.90% pure tungsten powder shaped into rounds and rectangles. It has a shiny, white metal surface and a density of over 17.5g/cm3. Tungsten bars are mainly used as additives in steel production or for spare parts in the semi-conductive and welding industries. Read More…

Edgetech Industries provides pure tungsten (rod, bar, sheet, plate, foil, crucible, tubing, customized parts), tungsten composites (CuW, CuWC, AgW, AgWC), tungsten alloys (W-Ni-Fe & W-Ni-Cu heavy alloys used as bucking bar, weights, radiation shielding, and raw tungsten (powder, trioxide, carbide) and granules/flux. We also provide tailor-made non-ferrous metals & alloys, rare earth elements,...

Titan International, Inc. is a dedicated supplier of quality products to the metal finishing industry. Through our partnering with a wide base of suppliers, Titan International is able to provide a broad metal product line. In addition to supplying high purity metals and metal powders, we will buy and/or sell your bulk scrap metal, including tungsten, tungsten carbide, nickel, and other metals.

Since 1987 our tungsten metal products have made us a leader in the worldwide market. Buffalo Tungsten is a tungsten supplier of tungsten metal powder & tungsten carbide powder used in tungsten bar & rod. Our tungsten wire is used in filament in light bulbs, electrical contacts & sports equipment.

At Global Tungsten & Powders (GTP), we have experience manufacturing and marketing products such as tungsten chemicals, tungsten carbide, and semi-finished tungsten parts. Industries we serve include aerospace, automotive, construction, and defense. We have established a global footprint for the production of tungsten materials by providing our customers with security of supply and continuous...

More Tungsten Bar Suppliers

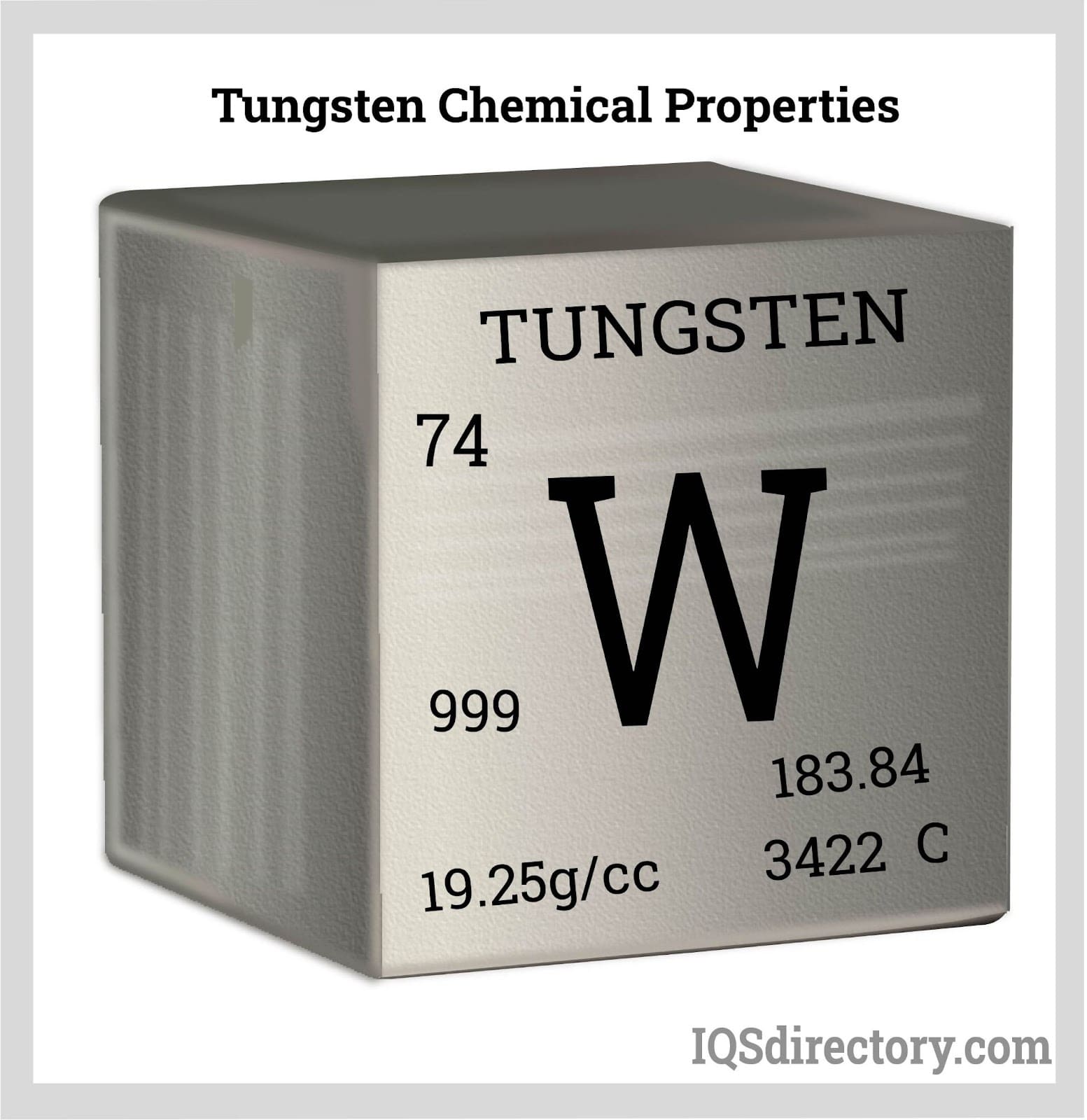

Tungsten Bars Physical and Chemical Properties.

There are three types of tungsten grades: TW-1, TW2, and TW-4. TW-1 is primarily utilized to manufacture spare parts for the semi-conductive, welding, etc. industries. TW-2 is utilized as a processing raw material. TW-4 is a steel manufacturing industry additive. TW-1 is primarily utilized to manufacture spare parts for semi-conductive, welding, etc. TW-2 is utilized as a processing raw material. TW-4 is a steel manufacturing industry additive.

Tungsten bars have a minimum density of 17.5g/cm3. Under typical atmospheric conditions, a tungsten bar maintains high stability and doesn’t react with water, air, or sulfuric acid (HCl). A mild reaction with acid begins when heated to about 80 and 100 °C. The bar easily oxidizes in an oxygen environment.

The Process of Producing Tungsten Bars

Tungsten bars are made using powder metallurgy. "Powder metallurgy" refers to the creation of materials or components from metal powders. Reducing or eliminating the requirement for subtractive manufacturing processes can cut material losses and lower the finished product cost. The process of production of tungsten bars is described below.

First, manufacturers reduce tungsten metal ore to a fine powder. Tungsten powder’s particle size and form vary depending on its purpose. Then the powder undergoes chemical processing to create tungsten oxide. The tungsten oxide is heated to transform the metal ore powder into pure tungsten powder. Then the pure powder is poured into a mold, then hydraulically pressed into a bar shape.

Next, the bar must be sintered. Sintering binds the metal powder further, preparing the bar for delivery to manufacturers. High-purity tungsten powder is made through complex chemical processes and filtration to achieve the required purity level. This consolidation entails several steps involving high temperatures, electrical current, and a hydrogen environment. The tungsten undergoes this process, condensing and hardening to become its bar form. Additional procedures are required to roll, draw, or flatten the bar into the desired form.

Tungsten bar Applications

The 99.999 percent pure tungsten bars are used as parts for high-standard bearing steels, automobiles, high-speed trains, extremely precise equipment, and cutting-edge weapons. The raw materials for ingredients are typically cast, unique steel is forged, and steel wires are typically drawn using 99.95 percent pure tungsten bars. Furthermore, it is widely employed in furnaces for sapphire crystals, vacuums, and high temperatures. Tungsten bar is also used to build ships, satellite airplanes, artillery rockets, and guns.

Advantages of Using Tungsten Bars

Resistance to high temperatures

Tungsten has the highest melting point among metals. In its most pure state, the melting point is (3422°C). This can be helpful in some circumstances, such as the construction, aircraft, and automation sectors. Alloys and superalloys are frequently made from tungsten metal. The alloy is strengthened by its unusually high melting point and thermal creep resistance, making it suitable for more thermally demanding applications where other metals would fail.

High-density

The density of tungsten among the highest of all metals, measuring 1.7 times greater than that of lead. Tungsten is frequently employed in applications where mass is needed in small proportions because of its ability to store a lot more weight in smaller packaging. Due to its high density, tungsten is a great material to use when creating kinetic munitions, airplane ballast, and racing car ballast, all of which need to be compact and streamlined while still being able to convey a lot of energy.

Additionally, it serves as a good substitute metal for manufacturing jewelry. Even though tungsten is only 0.35 percent less dense than gold, it is significantly more affordable than gold. Tungsten is often used to create fake gold bars. Lastly, due to its high density, tungsten is frequently used to make heavy metal alloys like high-speed steel. However, tungsten's density can also be advantageous when mixed with nickel, copper, iron, and other materials.

Low thermal expansion

Tungsten has the lowest thermal expansion coefficient compared to any pure metal. This gives tungsten increased stability at high heat compared to typical production materials (like steel, for example). It is especially helpful when rigidity at high temperatures is required. For example, rigidity is required in tungsten carbide cutting tools or jet engine turbine blades because it possesses a structural solidity unequaled by other metals.

Electronic structure

Tungsten metal is often used in the electronics sector, particularly in settings with high radiation levels, because of its conductive qualities and relative inertness. Tungsten is one of the sources of metal for X-ray targets because it has high-energy radiation shielding and a high density, making it challenging for x-rays to penetrate. Additionally, tungsten metals are often used in electrodes, conductors, and metallic coatings.

Choosing the Right Tungsten Bar Manufacturer

To make sure you have the most beneficial outcome when purchasing tungsten bars from a tungsten bar manufacturer, it is important to compare at least 5 companies using our list of tungsten bar manufacturers. Each tungsten bar manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each tungsten bar business website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple tungsten bar businesses with the same quote.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

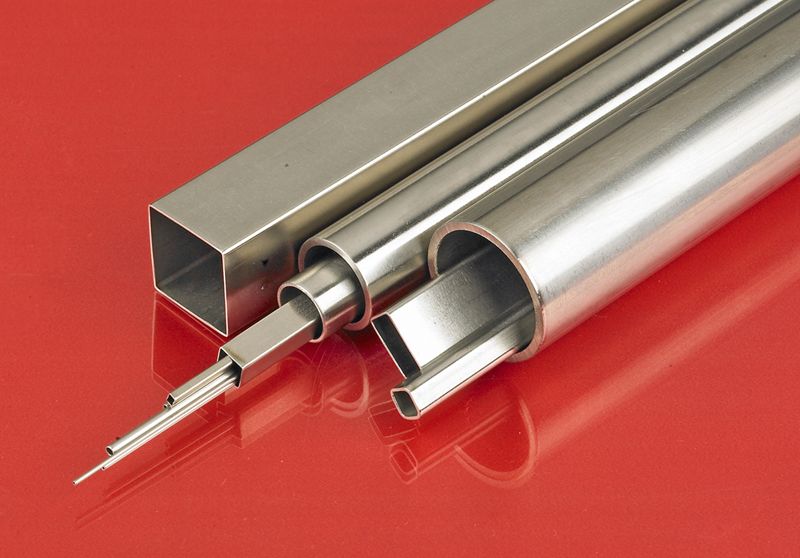

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services