Tungsten alloys, known as heavy alloys, are 90–97% tungsten with other metals added to increase the alloy’s ductility. Tungsten alloys are determined by manufacturers separately and cannot be standardized like steel or aluminum alloys. Therefore, there is no real naming standard for them. Tungsten alloys have the greatest melting point of any metal, good high-temperature strength, excellent creep resistance, great thermal conductivity, electrical conductivity, and electron emission performance. Read More…

Edgetech Industries provides pure tungsten (rod, bar, sheet, plate, foil, crucible, tubing, customized parts), tungsten composites (CuW, CuWC, AgW, AgWC), tungsten alloys (W-Ni-Fe & W-Ni-Cu heavy alloys used as bucking bar, weights, radiation shielding, and raw tungsten (powder, trioxide, carbide) and granules/flux. We also provide tailor-made non-ferrous metals & alloys, rare earth elements,...

Titan International, Inc. is a dedicated supplier of quality products to the metal finishing industry. Through our partnering with a wide base of suppliers, Titan International is able to provide a broad metal product line. In addition to supplying high purity metals and metal powders, we will buy and/or sell your bulk scrap metal, including tungsten, tungsten carbide, nickel, and other metals.

Since 1987 our tungsten metal products have made us a leader in the worldwide market. Buffalo Tungsten is a tungsten supplier of tungsten metal powder & tungsten carbide powder used in tungsten bar & rod. Our tungsten wire is used in filament in light bulbs, electrical contacts & sports equipment.

At Global Tungsten & Powders (GTP), we have experience manufacturing and marketing products such as tungsten chemicals, tungsten carbide, and semi-finished tungsten parts. Industries we serve include aerospace, automotive, construction, and defense. We have established a global footprint for the production of tungsten materials by providing our customers with security of supply and continuous...

More Tungsten Alloy Suppliers

Types of Tungsten Alloys

Tungsten Nickel Copper

The tungsten nickel-copper alloys have great mechanical strength and excellent electrical conductivity and are simple to produce. They can shield from radiation and have great thermal stability. Tungsten nickel-copper alloys are less ductile than nickel-iron alloys. However, they are not magnetic, making them a good substitute in some contexts. Oncology instruments, electrical sensor shields, guidance system components, and military technology use tungsten nickel copper.

Tungsten Carbide

The most significant tungsten alloy is tungsten carbide. It is also known as a tungsten-cobalt alloy because it consists of tungsten, carbon, and cobalt. Tungsten carbide (also referred to as "industrial teeth") is hard, strong, and corrosion-resistant. Cutting tools, blades, cobalt tools, and wear-resistant components are all made with carbide.

Carbide is currently used extensively in the aerospace and military industries. Demand will continue to increase with future developments of high-tech weaponry and technology.

Tungsten Nickel Iron Alloy

Tungsten nickel-iron alloys are superior in ductility, strength, and density. These alloys can endure extremely high temperatures, have good machining properties, and have a thermal conductivity five times greater than die and punch steels. If these alloys are intended to be used in magnetism-sensitive procedures, such as medical imaging equipment, it is crucial to understand that iron makes them magnetic. Tungsten nickel-iron alloys are resistant to elastic deformation and, therefore, ideal for glass-to-metal sealing. These alloys work well for radiation shielding, ballasts, bearing assembly, defense applications, and balance weights.

Applications of Tungsten Alloys

- Permanent magnets: Tungsten steel is used to create permanent magnets. A metal's or alloy's magnetic characteristics are highly sensitive to microstructure. When tungsten is present in steel in these proportions, for instance, it stabilizes the martensite phase, which has higher ferromagnetism than the ferrite (iron) phase due to its greater resistance to magnetic domain wall motion, although tungsten is not a ferromagnetic element.

- Industry: Tungsten is primarily used to manufacture tungsten carbide (WC), one of the toughest carbides. Tungsten carbide is used by metalworking, woodworking, mining, petroleum, and construction industries to create wear-resistant abrasives and cutting instruments such as knives, drills, circular saws, dies, milling, and turning tools. About 60% of the world's tungsten consumption is currently attributed to this industrial use.

- Jewelry: The jewelry industry produces rings made of sintered tungsten carbide, tungsten carbide/metal composites, and metallic tungsten. Nickel is used as the metal matrix in WC/metal composite rings rather than cobalt because it takes on a higher sheen when polished. Tungsten carbide is ceramic, even though producers and merchants occasionally refer to it as a metal. Rings constructed of tungsten carbide are exceptionally abrasion resistant and will maintain a burnished polish longer than rings made of metallic tungsten. However, tungsten carbide rings are fragile and may break when struck hard.

Choosing the Proper Tungsten Alloy Supplier

To make sure you have the most productive outcome when purchasing tungsten alloys from a tungsten alloy supplier, it is important to compare at least 4 to 5 suppliers using our tungsten alloy directory. Each tungsten alloy supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each tungsten alloy company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple tungsten alloy companies with the same form.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

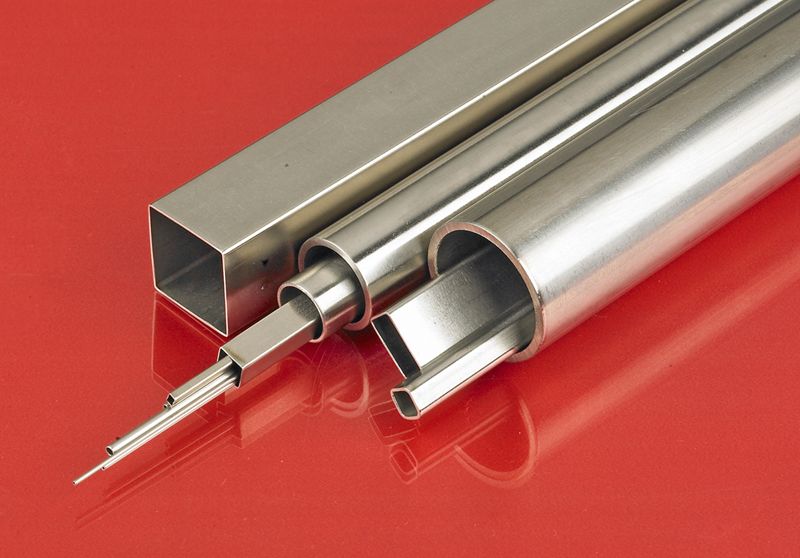

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services