This highly pure state is extremely electrically conductive and is primarily used in electrical applications, along with organic dyes, pigment phosphors and x-ray screens. Tungsten has been used for a number of years in various industries. Tungsten is valued for its resistance to heat and chemicals, as well as for its ability to increase hardness of metals when used as an alloy. Read More…

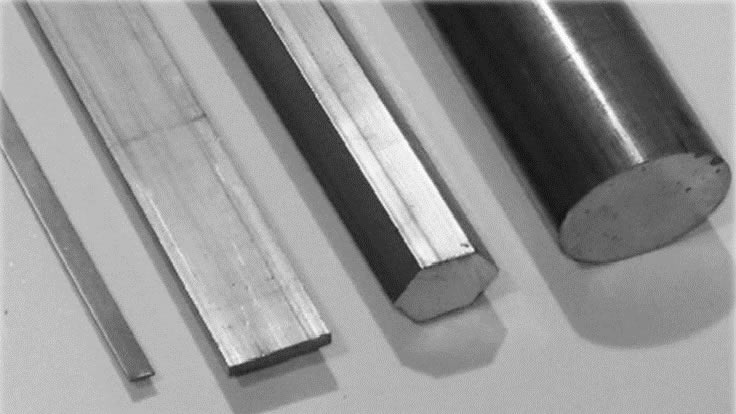

Edgetech Industries provides pure tungsten (rod, bar, sheet, plate, foil, crucible, tubing, customized parts), tungsten composites (CuW, CuWC, AgW, AgWC), tungsten alloys (W-Ni-Fe & W-Ni-Cu heavy alloys used as bucking bar, weights, radiation shielding, and raw tungsten (powder, trioxide, carbide) and granules/flux. We also provide tailor-made non-ferrous metals & alloys, rare earth elements,...

Titan International, Inc. is a dedicated supplier of quality products to the metal finishing industry. Through our partnering with a wide base of suppliers, Titan International is able to provide a broad metal product line. In addition to supplying high purity metals and metal powders, we will buy and/or sell your bulk scrap metal, including tungsten, tungsten carbide, nickel, and other metals.

Since 1987 our tungsten metal products have made us a leader in the worldwide market. Buffalo Tungsten is a tungsten supplier of tungsten metal powder & tungsten carbide powder used in tungsten bar & rod. Our tungsten wire is used in filament in light bulbs, electrical contacts & sports equipment.

At Global Tungsten & Powders (GTP), we have experience manufacturing and marketing products such as tungsten chemicals, tungsten carbide, and semi-finished tungsten parts. Industries we serve include aerospace, automotive, construction, and defense. We have established a global footprint for the production of tungsten materials by providing our customers with security of supply and continuous...

More Tungsten Powder Suppliers

Tungsten powder is prepared by hydrogen reduction, which is capable of producing tungsten powder with many different grain sizes. Tungsten powder has often been pressed into bars, sintered and forged into thin rods and used to create bulb filaments. Tungsten powder is also used in electrical contacts, airbag deployment systems and as the primary material used to produce tungsten wire. The powder is also used in other automotive and aerospace applications.

Purity of the powder is important, and depends on its intended use. Tungsten powder comes packaged in lined drums and can be produced to custom specifications. In the early 1900's, tungsten powder metallurgy began and tungsten became very popular because of its versatility and characteristics. In powder metallurgy, it is possible to create parts and components that would otherwise disintegrate. Tungsten powder adds strength to other metals when it is added, making it very important to manufacturers.

Because tungsten is a stable element, tungsten powder is believed to have no harmful effects on human health outside of possible irritation to the eyes and lungs if exposed. Due to its significant weight, the use of tungsten powder in military applications is thought to be superior than the more commonly used material, lead. Though tungsten, when a solid material, is difficult to manufacture due to its excessive hardness, when a powder, it can be compacted, thus more easily handled.

The many benefits of using tungsten powder are due to its purity and particle size. Depending on the quality of the particle grading and the consistency of the particle shapes, powdered tungsten, when pressed together within a bullet at pressures of 20,000 to 50,000 pounds per square inch (psi), will break apart on impact and spread excessively over a wide area, accomplishing a greater intended result. Air spaces between irregular-shaped particles cause the powder to lump, ultimately decreasing its effectiveness. Hydrogen-reduced tungsten powder, when faultlessly graded, can provide close to the same amount of compacted density as a solid metal.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

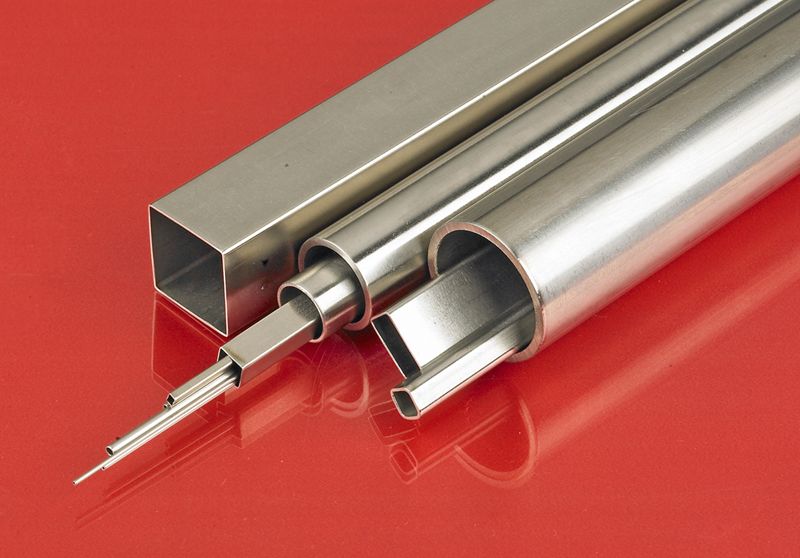

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services