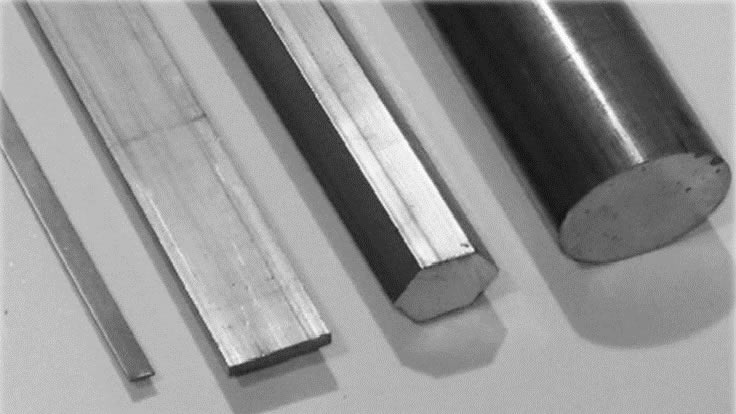

Tungsten sheet is a thin, flat metal material made from tungsten, known for its high density, strength, and exceptional heat resistance. It is created in sheet form to provide a versatile and durable material for applications such as electrical contacts, heating elements, radiation shielding, and various industrial uses requiring robust and reliable metal components. Read More…

Edgetech Industries provides pure tungsten (rod, bar, sheet, plate, foil, crucible, tubing, customized parts), tungsten composites (CuW, CuWC, AgW, AgWC), tungsten alloys (W-Ni-Fe & W-Ni-Cu heavy alloys used as bucking bar, weights, radiation shielding, and raw tungsten (powder, trioxide, carbide) and granules/flux. We also provide tailor-made non-ferrous metals & alloys, rare earth elements,...

Titan International, Inc. is a dedicated supplier of quality products to the metal finishing industry. Through our partnering with a wide base of suppliers, Titan International is able to provide a broad metal product line. In addition to supplying high purity metals and metal powders, we will buy and/or sell your bulk scrap metal, including tungsten, tungsten carbide, nickel, and other metals.

Since 1987 our tungsten metal products have made us a leader in the worldwide market. Buffalo Tungsten is a tungsten supplier of tungsten metal powder & tungsten carbide powder used in tungsten bar & rod. Our tungsten wire is used in filament in light bulbs, electrical contacts & sports equipment.

At Global Tungsten & Powders (GTP), we have experience manufacturing and marketing products such as tungsten chemicals, tungsten carbide, and semi-finished tungsten parts. Industries we serve include aerospace, automotive, construction, and defense. We have established a global footprint for the production of tungsten materials by providing our customers with security of supply and continuous...

More Tungsten Sheet Suppliers

Creation of Tungsten Sheet

Tungsten sheet is produced through various manufacturing methods, each tailored to specific applications. Sintering, a commonly used technique, involves compressing and heating powdered tungsten to form a solid sheet. This method finds application in the creation of electrical contacts. Rolling and annealing processes, meanwhile, result in tungsten sheets suitable for heating elements. Additionally, powder metallurgy offers an effective approach for manufacturing tungsten sheets used in radiation shielding.

Regulations and Standards for Tungsten Sheet

In the United States, the production and use of tungsten sheet are subject to regulations and standards aimed at ensuring safety, environmental protection, and compliance with quality requirements. These regulations are enforced by various agencies and bodies responsible for overseeing different aspects of tungsten sheet manufacturing and usage.

One specific regulation pertaining to tungsten and its alloys is the Toxic Substances Control Act (TSCA). TSCA is administered by the United States Environmental Protection Agency (EPA) and regulates the manufacture, import, processing, distribution, and use of chemical substances. Tungsten and tungsten compounds, including those used in tungsten sheet production, fall under the purview of TSCA. Under TSCA, manufacturers and importers of chemical substances, including tungsten-based materials, are required to submit pre-manufacture notifications to the EPA before introducing new substances into commerce. This helps ensure that potential risks associated with these substances are evaluated and appropriate measures are taken to protect human health and the environment.

Additionally, various Occupational Safety and Health Administration (OSHA) standards may apply to tungsten sheet manufacturing facilities to protect the health and safety of workers. These standards cover areas such as occupational exposure limits, respiratory protection, personal protective equipment, and hazard communication. It's important to note that specific regulations and standards may evolve over time, so it's essential for tungsten sheet manufacturers and users to stay updated with the latest requirements from regulatory authorities such as the EPA and OSHA, as well as any local, state, or industry-specific regulations that may apply.

Considerations Regarding Tungsten Sheet

While tungsten sheet offers numerous advantages, there are certain considerations that need to be addressed. Environmental impact and health concerns associated with the extraction and manufacturing of tungsten are notable challenges. These include the potential release of hazardous substances and the energy-intensive nature of tungsten production.

The Response of Tungsten Sheet Manufacturers

Recognizing the importance of sustainable practices and responsible manufacturing, tungsten sheet manufacturers have actively taken steps to address these considerations. Their extensive research and development efforts are focused on developing cleaner and more efficient production techniques. Manufacturers also prioritize the implementation of sustainable practices, such as minimizing waste generation and energy consumption, as well as adopting recycling and waste management initiatives. Their collaboration with regulatory agencies further ensures compliance with environmental standards and the continuous improvement of manufacturing processes.

Benefits of Tungsten Sheet

Tungsten sheet offers a plethora of advantages that contribute to its widespread use in various industries. Its high density and strength make it ideal for applications requiring robust and durable materials. Tungsten sheet also excels in heat resistance, with the ability to withstand extremely high temperatures without deformation or degradation. Additionally, tungsten sheet exhibits remarkable corrosion and wear resistance properties, enhancing their longevity and reliability.

Applications of Tungsten Sheet

Tungsten sheet finds extensive use across several industries. In the aerospace sector, tungsten sheets are employed in aircraft components, such as control surfaces and shielding materials. The defense industry benefits from their use in armor-piercing projectiles and radiation shielding. Tungsten sheets also play a critical role in medical applications, including X-ray targets, radiation therapy equipment, and medical imaging devices. Furthermore, their excellent electrical conductivity makes them valuable in electronics and electrical applications.

The Future and Tungsten Sheet

The future of tungsten sheet holds great promise. Ongoing advancements in technology and manufacturing processes are expected to enhance its properties and open up new avenues for its utilization. As industries strive for sustainability and environmental responsibility, tungsten sheet manufacturers will likely continue to innovate and implement greener practices, ensuring the continued growth of this versatile material.

Choosing the Right Tungsten Sheet Manufacturer

To ensure you have the most beneficial outcome when purchasing tungsten sheet from a tungsten sheet manufacturer, it is important to compare several companies using our directory of tungsten sheet manufacturers. Each tungsten sheet manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each tungsten sheet business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple tungsten sheet manufacturers with the same form.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

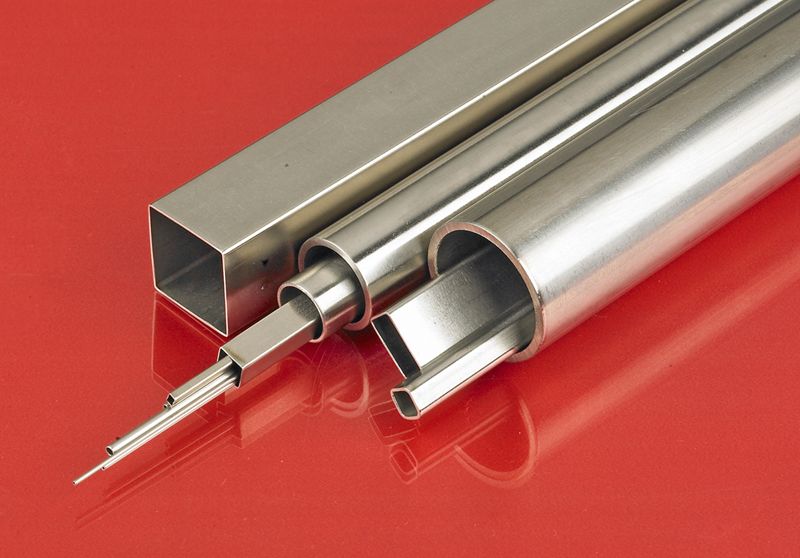

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services