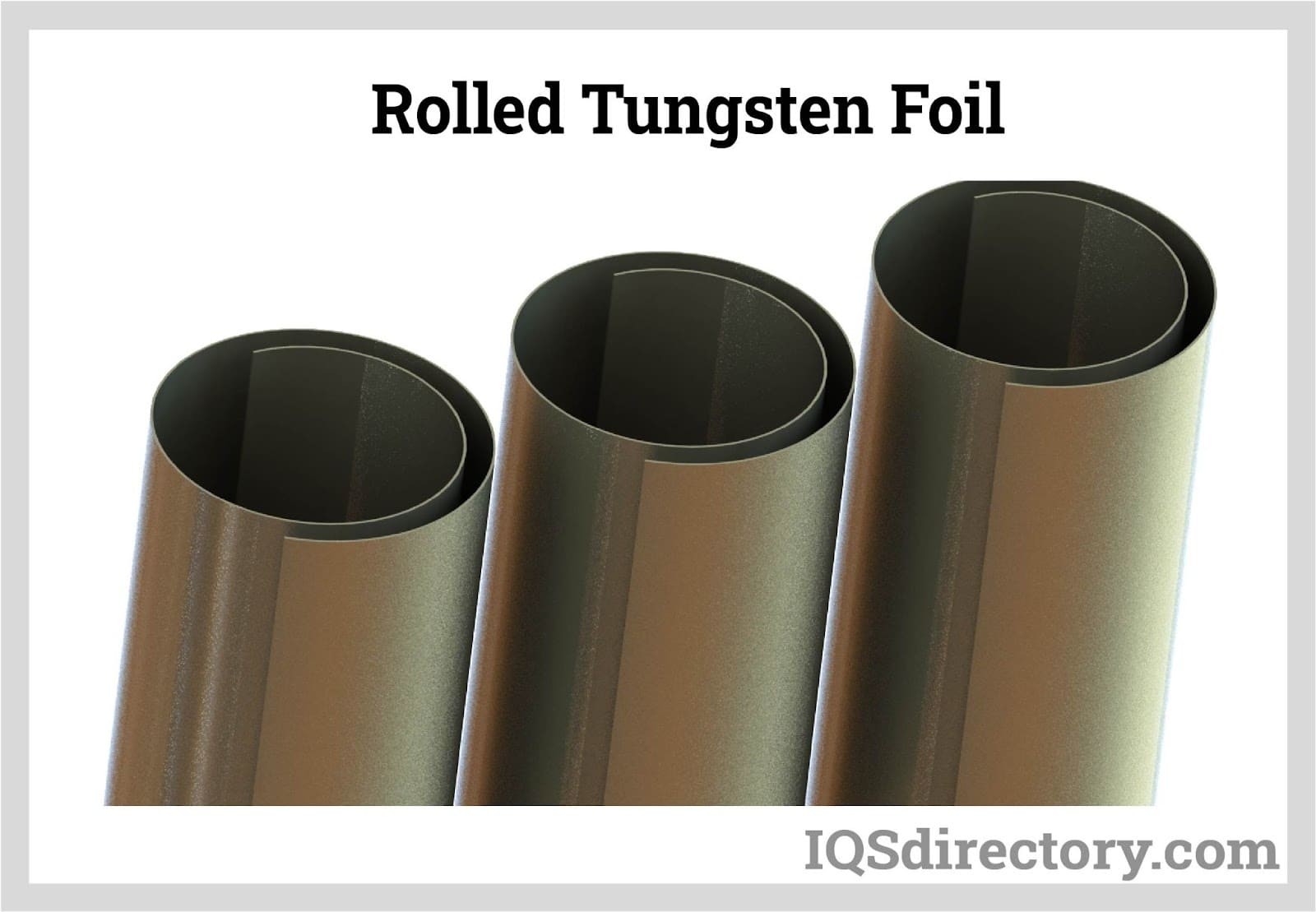

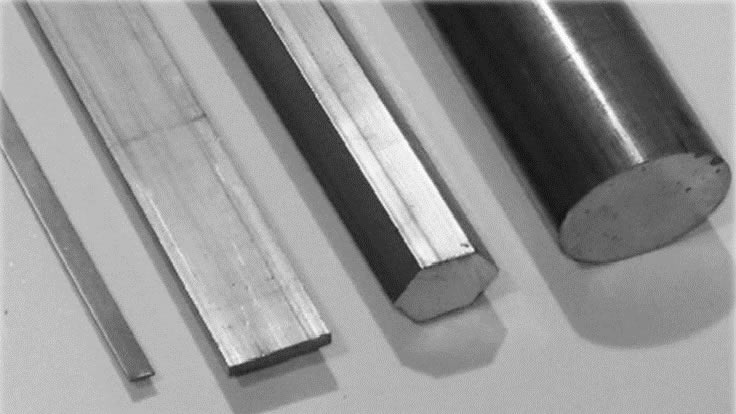

Tungsten foil is a type of metal foil consisting of tungsten. It has a flat, smooth surface with a black metallic sheen. Tungsten sheets are cold rolled to a thinner thickness to create tungsten foil. Stamped and drawn tungsten foil are used in high-temperature vacuum furnaces, coating, electronics, and semiconductor components. Heat shielding, heating elements, and vacuum furnace carriers are made of tungsten foil. The foil’s thinness makes it ideal for implanting in laminates, other metals, and glass. Read More…

Edgetech Industries provides pure tungsten (rod, bar, sheet, plate, foil, crucible, tubing, customized parts), tungsten composites (CuW, CuWC, AgW, AgWC), tungsten alloys (W-Ni-Fe & W-Ni-Cu heavy alloys used as bucking bar, weights, radiation shielding, and raw tungsten (powder, trioxide, carbide) and granules/flux. We also provide tailor-made non-ferrous metals & alloys, rare earth elements,...

Titan International, Inc. is a dedicated supplier of quality products to the metal finishing industry. Through our partnering with a wide base of suppliers, Titan International is able to provide a broad metal product line. In addition to supplying high purity metals and metal powders, we will buy and/or sell your bulk scrap metal, including tungsten, tungsten carbide, nickel, and other metals.

Since 1987 our tungsten metal products have made us a leader in the worldwide market. Buffalo Tungsten is a tungsten supplier of tungsten metal powder & tungsten carbide powder used in tungsten bar & rod. Our tungsten wire is used in filament in light bulbs, electrical contacts & sports equipment.

At Global Tungsten & Powders (GTP), we have experience manufacturing and marketing products such as tungsten chemicals, tungsten carbide, and semi-finished tungsten parts. Industries we serve include aerospace, automotive, construction, and defense. We have established a global footprint for the production of tungsten materials by providing our customers with security of supply and continuous...

More Tungsten Foil Suppliers

Tungsten Foil Features

- Tungsten sheets have a glittering silver shine on their surface.

- Tungsten foils have a radiation shielding property comparable to a lead plate.

- Tungsten sheets are easier to manufacture than lead and are thin enough to be punctured with tools as simple as regular household scissors.

- The foil is strong enough to withstand repeated bending, folding, and retraction.

- Tungsten foil is simple to use and poses no environmental hazards.

- Tungsten foil has excellent thermal plasticity. Therefore, molding into objects with cylinder-shaped or intricately curved surfaces is easy.

Tungsten Foil Production Process

The tungsten sheet is cold rolled to a thinner thickness to create tungsten foil. A powder made from mined tungsten ore is formed into a bar shape, then cold or hot-rolled into flat sheets and flattened into a foil. This process uses vacuum annealing furnaces for heating and cooling steps to fortify tungsten. Different mills, straighteners, hydraulic plate shears, water jets, and pressing machines are used to turn tungsten into foils. Sintering is an essential step in the production of tungsten foils, which are made from tungsten bars.

The tungsten bar is rolled through a press, which applies enormous pressure to compress the metal and consolidate the tungsten particles. The outcome is a delicate, extremely thin tungsten foil. The foil has a wide range of widths and can be rolled to a thickness of merely 0.001 inches. Tungsten foil can be available as sheets or coils. While tungsten foils can be finished in various ways, they typically resemble steel.

Uses of Tungsten Foil

Tungsten foil works extremely well in high-temperature environments, so it is often a component of industrial furnaces. Tungsten foil also has a high melting point and an exceptionally low vapor pressure. It is used to create evaporation boats and semiconductor components. Tungsten is a material that merits additional investigation for medicinal and sputtering applications. Other uses of tungsten foil include:

- Furnace pillars for vacuum furnaces.

- Tungsten headgear for the quartz industries.

- Stirring bars for rear-earth and glass smelting.

- Large tungsten hammers.

- Securing rods.

- Bolts, screws, and other fasteners.

- Electrodes for the rare earth metal and welding industries

- Ion implantation parts can be processed using a cold-rolled tungsten plate.

- Electric vacuum devices and parts for electric light sources are made with them.

- Tungsten makes up high-temperature furnace heating bodies, heat-insulating screens, and tungsten boats.

- It serves as a target for tungsten sputtering.

Choosing the Right Tungsten Foil Company

To make sure you have the most productive outcome when purchasing tungsten foil from a tungsten foil company, it is important to compare at least 5 companies using our tungsten foil directory. Each tungsten foil company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each tungsten foil business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple tungsten foil companies with the same message.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services